So, is there a perfect row unit for every condition and situation? In my experience I have yet to find one. Selecting a row unit and attachments that can go from no-till in heavy clay to conventionally worked ground in near perfect soil is hard as each one has their fit, but none seem to be truly universal. What works in one condition more than likely will not work in another.

After a discussion with a few guys on newagtalk.com including Matt

Hagny from Exapta Solutions, www.exapta.com I thought I should lay out

my thoughts on row units from experience and studying research trials.

Row Cleaners

|

| Floating Martin-Till Row Cleaners |

The leading edge of any row unit should have them, even in worked ground. Cleaning residue from the seed trench and ahead of the disk openers is a must. Running row cleaners just at soil level so they move about 50% of the time is where you should set them. Residue that gets into the disk openers can cause several issues especially hair pinning residue in the seed trench preventing even emergence and closing. In the fixed vs. floating debate, floating is better than fixed row cleaners especially in variable field conditions. I've seen row cleaners set up for no-till in a field that has both worked and no-till that plowed in the worked ground. Plowing with row cleaners to get to moisture or for other reasons will put seed in cold soil and create a trench to capture and channel moisture.

Seed Firmers

Seed firmers are designed to run behind the seed tube and push seed to the bottom of the trench. In worked ground, or heavy soils this attachment is invaluable. Some will argue that mud will ball up on them and drag seed, but if you are planting in conditions that mud would collect on firmers you shouldn't be planting. Another instance you should consider firmers is where you are using offset disk openers and/or RID gauge wheels which you will see on Case IH planters.

To Coulter or Not to Coulter

A lot of "no-till" planters have just a single coulter ahead of the disk openers, while others like the picture above will have them just behind row cleaners. The idea behind coulters is to lightly work the soil ahead of the disk openers and in heavy soil no-till situations this has a place. Running just a coulter will also hairpin residue in the seed trench in both worked and no-till situations. Ideally, coulters are only needed in no-till planting into heavy soils. Remember to run them just above the seed trench, this can be set by putting the row unit on a level surface and adjusting them accordingly.

Closing Wheels

|

| Schlagel Posi Close Wheels |

There are many versions of closing wheels on the market now and many of them do the same job. The standard closing wheel configuration is two rubber wheels and in worked soils this is still the best setup to run. In heavy soils and no-till I have seen good performance from the Schlagel Posi Close wheels that give some down pressure while not creating a zone that can crack if conditions get wet then dry. Another setup that works in these conditions with ability to move to good worked ground is one spiked closing wheel like a Yetter 13" spike along with a rubber wheel. One thing to caution running aggressive spiked closing wheels is to be careful with popping seed out of the trench. This can be alleviated by running a seed firmer.

*A side note on treader wheel closing systems like Case IH and cotton closing systems from John Deere

In near perfect conditions these systems can do a decent job, but in heavier soils seed trench closing and emergence can be hampered by using these systems.

Gauge Wheels

On the market right now we basically have two types of gauge wheels, traditional and Reduced Interior Diameter (RID). RID wheels have a narrow footprint with an indentation near the disk openers that is supposed to create a lifting effect next to the seed trench to minimize gauge wheel compaction. This lifting effect also can create air pockets in the trench leading to other wheels. Ideally running traditional gauge wheels you would adjust your down pressure to minimize sidewall compaction in the trench.

Disk Openers

There are also two configurations for disk openers, offset and side by side. The offset creates a shallower angle in the seed furrow leaving seed sometimes hanging up shallower than intended. Traditional disk opener setups with a seed firmer appear to be the winners here as well.

To me the perfect row unit in perfect soil conditions would have floating trash wheels with a seed firmer, past that any other configuration of the above parts would work. In tough conditions I would be looking at regular gauge wheels and disk openers along with a spiked/rubber wheel closing system or Schlagel Posi Close with or without a coulter.

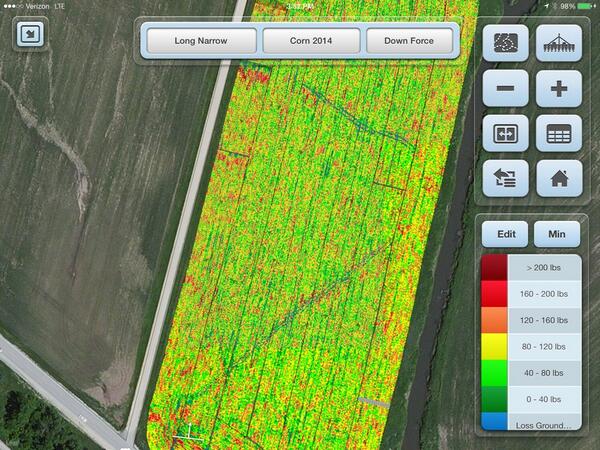

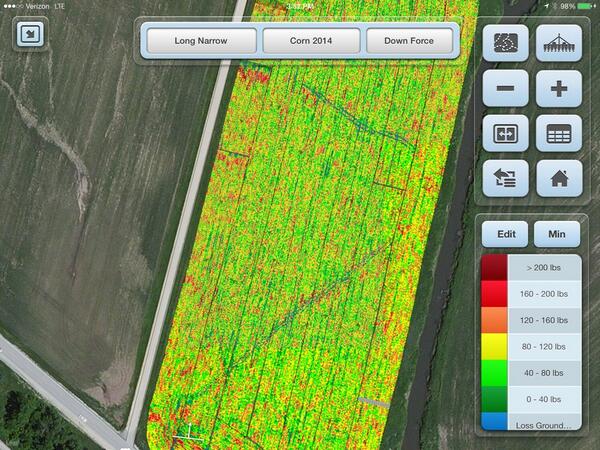

Down Pressure

|

| Truck tracks picked up by Delta Force via Dustin Spears @dspears2 |

The one thing that is interesting to watch is the development in down pressure with hydraulic systems getting more acres through them. Setting a planter's down pressure one time per field is not ideal when you are constantly changing conditions across a field along with losing weight from using seed and fertilizer. The newer air and hydraulic systems adjust on the go to give you enough down force or in some cases lift to keep the proper ground contact and consistent seed placement. Here is an interesting twitter post from Dustin Spears showing how Delta Force from Precision Planting picked up and adjusted for pickup truck tire tracks on the fly. https://twitter.com/dspears2/status/457623435783319552

|

| https://www.youtube.com/watch?v=7j578ZuiTPk |

There are several sources to go to for good data on what row units and attachments work in various conditions. I was at the 2013 Precision Planting winter conference to see this presentation by Cory Muhlbauer about their research on row units. Their findings are similar to mine, in perfect conditions row units perform similar, but in tough soils like we have in SE Wisconsin there are differences. Spending time getting your planter setup for your conditions is one of the most important things you can do on your farm. If you have questions about what planter row unit setup does well in your area work with an agronomist who has knowledge of different setups and how they perform on your soils.

No comments:

Post a Comment