As we enter the '16 crop season there seems to be more questions and uncertainty in the country than answers and guidance. Over the past couple seasons I have been working with several growers on preparing for a downturn in crop prices and managing through these times. Below are several of the strategies we have been working on that have worked so far.

Examine Your Low Producing Acres

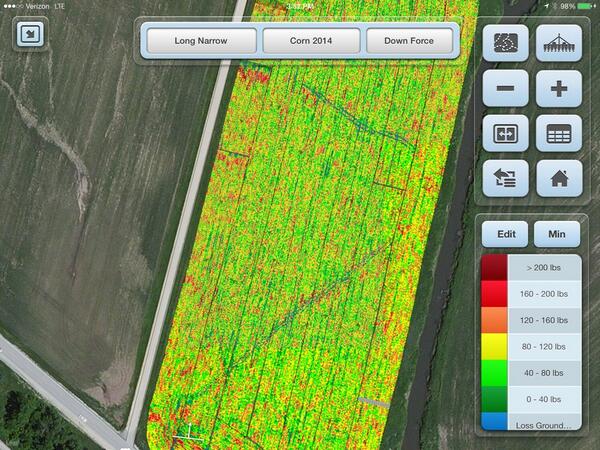

We do an excellent job managing our good acres, but seem to put low producing acres on the back burner. Our good producing acres make us money, but your lowest production ground loses you money. While a field can still get you a good overall yield, putting the same fertilizer and inputs into low yielding areas as your top areas costs you money. The key for us has been using the tools we have to manage these areas so we don't put money where it's not needed. 3-5 years of good yield data can help you to determine these areas and apply fertilizer accordingly. VRT fertilizer based on crop removal and variable rate nitrogen can reduce the amount of inputs you put on areas that will just not get you the return on investment you need. The biggest thing for us the past few years has been finding these areas and determining what's the reason for their lower production. Sometimes its something simple like compaction, or fertility and in some cases they are just low producing soil that will never come up to meet the average for the field. Fixing problem spots is probably the most rewarding feeling I've had, and everyone knows what its like to have a good average going then watching it go down when you take off these spots in every field.

Spread Your Risk With Land Leases

Over 80% of agricultural land is rented, and most use the same contract to lock these acres up for a few years. If you ever talk to someone who does snowplowing in winter they typically spread their risk by three types of contracts; 1/3 are by the inch, 1/3 are by the snowfall, and 1/3 are by the season. Whether they have a low snowfall season, a season with several small snowfalls, or a few big snowfalls they are covered. A typical lease agreement in agriculture is so much for every acre a year over a certain amount of years. Try doing three different kinds of leases; a certain amount per year, yield based, and market based. Flex rent contracts are a way to hedge your risk on a certain amount of your land. Determining the land owners who will fit each type of contract is key. Just like marketing, it's all about spreading your risk.

Take the Emotion out of Marketing

If you trade stocks or have investments we all know it's about the long haul. I'll be honest, I've hit a few big trades but I've also taken a few bad investments(including one stock that I still own that's lost over 50% of it's value). The biggest thing I have learned working with grain merchandisers and investment "experts" is that you have to take the emotion out of any market. Markets don't have to do anything, and often will do what we don't expect. I work with growers on establishing their breakeven per acre and per bushel to determine when we should be marketing grain. Some years we don't get the highest price, but we try to focus on average prices above our costs IE. ROI. The biggest breakthrough we had was a few years ago when we started marketing grain every time we got any kind of selling signal. Even if you think the market may go up you should sell some amount of grain if you are thinking about it, we've hit more of the up days in a rally this way. If you work with a merchandiser capable of doing puts and calls take advantage of them, again hedge your risk. Leave the coffee shop talk to someone else, worry about making the most per acre over the long run not who sold one contract for the most.

Evaluate Equipment Costs

A couple years ago I had a grower ask me about whether he should by a draper head or not. When we looked at the return per acre it was impressive, but when we figured out the years and acres it would take to pay for his investment he determined it wasn't worth it at the time. I think we should all be doing this on every piece of equipment you own. Having fresh paint around is always nice, but does it make you money? Figure out your annual repair costs, and potential down time with the equipment you have. If it doesn't gain you enough to get a return on your investment in a few years then it might not be worth making a trade. That goes both ways as well, if a piece of equipment you have doesn't pay for itself already maybe it's something to consider trying to use one piece of equipment to do what you did with two. A couple of the growers I work with had a tractor that did only one job every year that could be taken over by another tractor that wasn't running another job that time of year.

Use a Farm Advisor, not a Salesman

Saving $10/ton on fertilizer on something you use 200#/acre saves you about $1/ac. While seed/chemicals/fertilizer is a large amount of your expenses they make up only about 40% of your overall input costs. Prices and programs can vary by supplier, but usually markets determine the costs your input supplier pay and they almost all buy for the same price. Lower prices typically follow lower service providers, so for a lower price you get little or no service. The key to all of this is working with someone who understands your goals and is willing to incorporate that into what they recommend and do for you. People who try to sell you products only to fix problems are just at your farm gate trying to sell you products, people who listen to your concerns and pay attention to your equipment, problems, and goals are there to work with you to make you better. I always tell my growers if they don't make money they won't buy anything from me and I'll be unemployed. If we are all in it for the long haul and are invested in each other, we should both be making money.

That's it, that's what I help my growers focus on in good years and help them prepare for the bad years. It's all about working with the right people, spreading your risk, making business decisions without emotion, and looking at the decisions you make with your bottom line in mind. It's not about who has the best equipment, or sold for the highest price; it's about preparing your operation to continue for the next generation and going to bed with no worries or regrets.

Certified Crop Advisor, BS from Purdue in Agronomy Crop and Soil Management. Providing crop advising and solutions based agronomy since 2008. Owner of Stull Agronomy LLC

Wednesday, September 30, 2015

Tuesday, December 23, 2014

Is There a "Perfect" Row Unit?

So, is there a perfect row unit for every condition and situation? In my experience I have yet to find one. Selecting a row unit and attachments that can go from no-till in heavy clay to conventionally worked ground in near perfect soil is hard as each one has their fit, but none seem to be truly universal. What works in one condition more than likely will not work in another.

After a discussion with a few guys on newagtalk.com including Matt Hagny from Exapta Solutions, www.exapta.com I thought I should lay out my thoughts on row units from experience and studying research trials.

Row Cleaners

The leading edge of any row unit should have them, even in worked ground. Cleaning residue from the seed trench and ahead of the disk openers is a must. Running row cleaners just at soil level so they move about 50% of the time is where you should set them. Residue that gets into the disk openers can cause several issues especially hair pinning residue in the seed trench preventing even emergence and closing. In the fixed vs. floating debate, floating is better than fixed row cleaners especially in variable field conditions. I've seen row cleaners set up for no-till in a field that has both worked and no-till that plowed in the worked ground. Plowing with row cleaners to get to moisture or for other reasons will put seed in cold soil and create a trench to capture and channel moisture.

Seed Firmers

Seed firmers are designed to run behind the seed tube and push seed to the bottom of the trench. In worked ground, or heavy soils this attachment is invaluable. Some will argue that mud will ball up on them and drag seed, but if you are planting in conditions that mud would collect on firmers you shouldn't be planting. Another instance you should consider firmers is where you are using offset disk openers and/or RID gauge wheels which you will see on Case IH planters.

To Coulter or Not to Coulter

A lot of "no-till" planters have just a single coulter ahead of the disk openers, while others like the picture above will have them just behind row cleaners. The idea behind coulters is to lightly work the soil ahead of the disk openers and in heavy soil no-till situations this has a place. Running just a coulter will also hairpin residue in the seed trench in both worked and no-till situations. Ideally, coulters are only needed in no-till planting into heavy soils. Remember to run them just above the seed trench, this can be set by putting the row unit on a level surface and adjusting them accordingly.

Closing Wheels

There are many versions of closing wheels on the market now and many of them do the same job. The standard closing wheel configuration is two rubber wheels and in worked soils this is still the best setup to run. In heavy soils and no-till I have seen good performance from the Schlagel Posi Close wheels that give some down pressure while not creating a zone that can crack if conditions get wet then dry. Another setup that works in these conditions with ability to move to good worked ground is one spiked closing wheel like a Yetter 13" spike along with a rubber wheel. One thing to caution running aggressive spiked closing wheels is to be careful with popping seed out of the trench. This can be alleviated by running a seed firmer.

*A side note on treader wheel closing systems like Case IH and cotton closing systems from John Deere

In near perfect conditions these systems can do a decent job, but in heavier soils seed trench closing and emergence can be hampered by using these systems.

Gauge Wheels

On the market right now we basically have two types of gauge wheels, traditional and Reduced Interior Diameter (RID). RID wheels have a narrow footprint with an indentation near the disk openers that is supposed to create a lifting effect next to the seed trench to minimize gauge wheel compaction. This lifting effect also can create air pockets in the trench leading to other wheels. Ideally running traditional gauge wheels you would adjust your down pressure to minimize sidewall compaction in the trench.

Disk Openers

There are also two configurations for disk openers, offset and side by side. The offset creates a shallower angle in the seed furrow leaving seed sometimes hanging up shallower than intended. Traditional disk opener setups with a seed firmer appear to be the winners here as well.

To me the perfect row unit in perfect soil conditions would have floating trash wheels with a seed firmer, past that any other configuration of the above parts would work. In tough conditions I would be looking at regular gauge wheels and disk openers along with a spiked/rubber wheel closing system or Schlagel Posi Close with or without a coulter.

Down Pressure

The one thing that is interesting to watch is the development in down pressure with hydraulic systems getting more acres through them. Setting a planter's down pressure one time per field is not ideal when you are constantly changing conditions across a field along with losing weight from using seed and fertilizer. The newer air and hydraulic systems adjust on the go to give you enough down force or in some cases lift to keep the proper ground contact and consistent seed placement. Here is an interesting twitter post from Dustin Spears showing how Delta Force from Precision Planting picked up and adjusted for pickup truck tire tracks on the fly. https://twitter.com/dspears2/status/457623435783319552

There are several sources to go to for good data on what row units and attachments work in various conditions. I was at the 2013 Precision Planting winter conference to see this presentation by Cory Muhlbauer about their research on row units. Their findings are similar to mine, in perfect conditions row units perform similar, but in tough soils like we have in SE Wisconsin there are differences. Spending time getting your planter setup for your conditions is one of the most important things you can do on your farm. If you have questions about what planter row unit setup does well in your area work with an agronomist who has knowledge of different setups and how they perform on your soils.

After a discussion with a few guys on newagtalk.com including Matt Hagny from Exapta Solutions, www.exapta.com I thought I should lay out my thoughts on row units from experience and studying research trials.

Row Cleaners

|

| Floating Martin-Till Row Cleaners |

Seed Firmers

Seed firmers are designed to run behind the seed tube and push seed to the bottom of the trench. In worked ground, or heavy soils this attachment is invaluable. Some will argue that mud will ball up on them and drag seed, but if you are planting in conditions that mud would collect on firmers you shouldn't be planting. Another instance you should consider firmers is where you are using offset disk openers and/or RID gauge wheels which you will see on Case IH planters.

To Coulter or Not to Coulter

A lot of "no-till" planters have just a single coulter ahead of the disk openers, while others like the picture above will have them just behind row cleaners. The idea behind coulters is to lightly work the soil ahead of the disk openers and in heavy soil no-till situations this has a place. Running just a coulter will also hairpin residue in the seed trench in both worked and no-till situations. Ideally, coulters are only needed in no-till planting into heavy soils. Remember to run them just above the seed trench, this can be set by putting the row unit on a level surface and adjusting them accordingly.

Closing Wheels

|

| Schlagel Posi Close Wheels |

*A side note on treader wheel closing systems like Case IH and cotton closing systems from John Deere

In near perfect conditions these systems can do a decent job, but in heavier soils seed trench closing and emergence can be hampered by using these systems.

Gauge Wheels

On the market right now we basically have two types of gauge wheels, traditional and Reduced Interior Diameter (RID). RID wheels have a narrow footprint with an indentation near the disk openers that is supposed to create a lifting effect next to the seed trench to minimize gauge wheel compaction. This lifting effect also can create air pockets in the trench leading to other wheels. Ideally running traditional gauge wheels you would adjust your down pressure to minimize sidewall compaction in the trench.

Disk Openers

There are also two configurations for disk openers, offset and side by side. The offset creates a shallower angle in the seed furrow leaving seed sometimes hanging up shallower than intended. Traditional disk opener setups with a seed firmer appear to be the winners here as well.

To me the perfect row unit in perfect soil conditions would have floating trash wheels with a seed firmer, past that any other configuration of the above parts would work. In tough conditions I would be looking at regular gauge wheels and disk openers along with a spiked/rubber wheel closing system or Schlagel Posi Close with or without a coulter.

Down Pressure

|

| Truck tracks picked up by Delta Force via Dustin Spears @dspears2 |

| https://www.youtube.com/watch?v=7j578ZuiTPk |

Tuesday, December 16, 2014

Why We Need Some Sort of UAV Regulation

I started using UAV's to scout fields in late 2012 in the early stages of interest in UAV use. It's amazing the advances we have had in two years with UAV technology. I started using a fairly rudimentary Parrot AR 2.0 Drone with a low mega pixel camera that is fixed on the front to now

using a DJI Phantom 2 with a Go Pro on a gimbal mount that shoots amazing HD pictures and video. We have used pictures to get a different perspective on field patterns and issues we would have never seen from the ground. For three years we have also been using thermal imagery from a plane to better identify stressed areas of fields overlooked by traditional field scouting. In several cases this information has proven invaluable to correcting or spotting errors and issues before they become problems.

The advances and increased availability of UAV's has also lead to issues that we cannot avoid. It's easy to see stories in the news recently of UAV's being used to take pictures and videos near airports, flying aircraft, and in populated areas and sporting events. Currently, UAV usage falls under hobby aircraft regulations; not to be used for profit, no flying over 400 feet, and not within five miles of airports. These rules are to keep hobby aircraft like remote controlled plains away from VFR (visual flight reference) aircraft. VFR rules govern aircraft use for aircraft flying using only visual reference to keep them away from other aircraft and regulating altitude based on sight. Aircraft flying in the US are regulated to maintain minimum altitudes of 500 feet over land and 1000 feet over populated areas.

It's not hard to find videos on YouTube of UAV's violating hobby aircraft flight rules. This is why we need some sort of regulation that UAV pilots can live by, and they need to be enforced. Proposed legislation by the FAA and members of government look to put UAV's into more regular flight rules. Proposed legislation would require typical pilot licensing, which includes 20-50 hours of flight time in an aircraft typically at a cost of $50-$100/hour with an instructor along with practical knowledge tests. While this would weed out the bad pilots it would also weed out people like me who want some regulation and licensing, but don't want to pay $5,000 to $6,000 to fly a UAV.

It's not hard to find videos on YouTube of UAV's violating hobby aircraft flight rules. This is why we need some sort of regulation that UAV pilots can live by, and they need to be enforced. Proposed legislation by the FAA and members of government look to put UAV's into more regular flight rules. Proposed legislation would require typical pilot licensing, which includes 20-50 hours of flight time in an aircraft typically at a cost of $50-$100/hour with an instructor along with practical knowledge tests. While this would weed out the bad pilots it would also weed out people like me who want some regulation and licensing, but don't want to pay $5,000 to $6,000 to fly a UAV.

Having a basic knowledge test, and a basic flight class along with carrying a license would be more acceptable. This would weed out bad pilots along with creating a set of rules that everyone can fallow and will have the knowledge and willingness to as well. While having a licensing requirement may keep away the hobbyist it will also bring in the people sitting on the outside waiting to see what regulation there will be on UAV's before they buy in. The largest growth and research continues to be in the higher technology and commercial UAV sector so I would doubt we would lose any interest and development in higher end UAV's by regulating the industry.

Of course UAV's take amazing pictures and video of equipment so if you like harvest videos like most people check out my YouTube of some of my videos from this fall at www.youtube.com/agryguy

|

| Down Corn we would have missed by walking field |

The advances and increased availability of UAV's has also lead to issues that we cannot avoid. It's easy to see stories in the news recently of UAV's being used to take pictures and videos near airports, flying aircraft, and in populated areas and sporting events. Currently, UAV usage falls under hobby aircraft regulations; not to be used for profit, no flying over 400 feet, and not within five miles of airports. These rules are to keep hobby aircraft like remote controlled plains away from VFR (visual flight reference) aircraft. VFR rules govern aircraft use for aircraft flying using only visual reference to keep them away from other aircraft and regulating altitude based on sight. Aircraft flying in the US are regulated to maintain minimum altitudes of 500 feet over land and 1000 feet over populated areas.

It's not hard to find videos on YouTube of UAV's violating hobby aircraft flight rules. This is why we need some sort of regulation that UAV pilots can live by, and they need to be enforced. Proposed legislation by the FAA and members of government look to put UAV's into more regular flight rules. Proposed legislation would require typical pilot licensing, which includes 20-50 hours of flight time in an aircraft typically at a cost of $50-$100/hour with an instructor along with practical knowledge tests. While this would weed out the bad pilots it would also weed out people like me who want some regulation and licensing, but don't want to pay $5,000 to $6,000 to fly a UAV.

It's not hard to find videos on YouTube of UAV's violating hobby aircraft flight rules. This is why we need some sort of regulation that UAV pilots can live by, and they need to be enforced. Proposed legislation by the FAA and members of government look to put UAV's into more regular flight rules. Proposed legislation would require typical pilot licensing, which includes 20-50 hours of flight time in an aircraft typically at a cost of $50-$100/hour with an instructor along with practical knowledge tests. While this would weed out the bad pilots it would also weed out people like me who want some regulation and licensing, but don't want to pay $5,000 to $6,000 to fly a UAV.Having a basic knowledge test, and a basic flight class along with carrying a license would be more acceptable. This would weed out bad pilots along with creating a set of rules that everyone can fallow and will have the knowledge and willingness to as well. While having a licensing requirement may keep away the hobbyist it will also bring in the people sitting on the outside waiting to see what regulation there will be on UAV's before they buy in. The largest growth and research continues to be in the higher technology and commercial UAV sector so I would doubt we would lose any interest and development in higher end UAV's by regulating the industry.

Of course UAV's take amazing pictures and video of equipment so if you like harvest videos like most people check out my YouTube of some of my videos from this fall at www.youtube.com/agryguy

Saturday, October 4, 2014

Do I Need to Worry About Rootworms in 2015?

I have been asked a lot about corn rootworm survival this season primarily about our wet June during traditional hatch times. In 2014, we had a hard cold winter that carried into planting with cool wet conditions during and after planting. June was especially wet with saturated conditions up to just after July 4th.

"So we had an overall lethal crop year for corn rootworm larvae and eggs right?" In most cases that would not be accurate. While we had severe cold with air temperatures in the -20F to -30F range for spells this winter, we still had very adequate snow cover that kept soil temperatures above zero all winter and in most cases it was closer to 10-15F above zero at the coldest. These soil temperatures and the snow cover likely kept most rootworm eggs viable over winter.

"Ok, ok . . the saturated soil conditions in June had to at least kill most of the remaining beetle eggs and larvae right?" That's also not entirely likely as beetle emergence and hatch was delayed a couple of weeks by cool conditions. Remember that corn rootworm egg hatch is closely tied to GDD accumulation during the growing season. They also don't all hatch at once, it is extended over about a months time during the summer. While saturated conditions will potentially kill hatching larvae, it will not kill eggs so if hatch was delayed to after the soil was saturated it likely didn't kill many of them.

"Well that can't be right, I didn't see any beetles scouting fields at silking or just after the completion of pollination." This was very true in 2014, I rarely ran into many beetles during pollination this year. I did however, start seeing them during grain fill and continue to notice more beetles than normal as we move closer to harvest. As we dug roots later in the season this year I have noticed significant feeding in areas of continuous corn, especially on single RW traited corn without insecticide. In one instance we have noticed plant lodging on single traited corn next to straight RR corn treated with Force insecticide. Do we have resistance issues, I don't think so at this time as it is more a result of pressure on COC acres than resistance but will need to be monitored in the future.

One observation over the past two months has been a significantly higher population of Northern Corn Rootworm than I have seen in the past. This is alarming due to the ability of Northern's to exhibit extended diapause meaning they can hatch later or in some instances two growing seasons later. So for 2015 I think that in COC we will have to consider dual modes of action in RW traits or at the very least insecticide on single traits. There is some elevated concern on rotated acres, but I think we are a year out before we see these Northerns cause major problems in rotated fields. With a potential for lower traited corn and reduced insecticide use at lower corn prices I think we will find out just what kind of pressure we have in 2015. I wouldn't count out rootworms being a major pest in 2015, they may surprise us all as they have in the past.

"So we had an overall lethal crop year for corn rootworm larvae and eggs right?" In most cases that would not be accurate. While we had severe cold with air temperatures in the -20F to -30F range for spells this winter, we still had very adequate snow cover that kept soil temperatures above zero all winter and in most cases it was closer to 10-15F above zero at the coldest. These soil temperatures and the snow cover likely kept most rootworm eggs viable over winter.

"Ok, ok . . the saturated soil conditions in June had to at least kill most of the remaining beetle eggs and larvae right?" That's also not entirely likely as beetle emergence and hatch was delayed a couple of weeks by cool conditions. Remember that corn rootworm egg hatch is closely tied to GDD accumulation during the growing season. They also don't all hatch at once, it is extended over about a months time during the summer. While saturated conditions will potentially kill hatching larvae, it will not kill eggs so if hatch was delayed to after the soil was saturated it likely didn't kill many of them.

"Well that can't be right, I didn't see any beetles scouting fields at silking or just after the completion of pollination." This was very true in 2014, I rarely ran into many beetles during pollination this year. I did however, start seeing them during grain fill and continue to notice more beetles than normal as we move closer to harvest. As we dug roots later in the season this year I have noticed significant feeding in areas of continuous corn, especially on single RW traited corn without insecticide. In one instance we have noticed plant lodging on single traited corn next to straight RR corn treated with Force insecticide. Do we have resistance issues, I don't think so at this time as it is more a result of pressure on COC acres than resistance but will need to be monitored in the future.

One observation over the past two months has been a significantly higher population of Northern Corn Rootworm than I have seen in the past. This is alarming due to the ability of Northern's to exhibit extended diapause meaning they can hatch later or in some instances two growing seasons later. So for 2015 I think that in COC we will have to consider dual modes of action in RW traits or at the very least insecticide on single traits. There is some elevated concern on rotated acres, but I think we are a year out before we see these Northerns cause major problems in rotated fields. With a potential for lower traited corn and reduced insecticide use at lower corn prices I think we will find out just what kind of pressure we have in 2015. I wouldn't count out rootworms being a major pest in 2015, they may surprise us all as they have in the past.

Saturday, August 23, 2014

What You Need to Know About Roundup Ready 2 Xtend and Enlist

If you haven't heard about Enlist and Roundup Ready 2 Xtend herbicide traits over the past two years you have been hiding under a proverbial agricultural rock. These traits will be here before you know it and will take some understanding and increased management on the part of retailers and farmers.

"Did you say increased management, I thought it was supposed to be easier?" While these technologies will make it easier to bring down weeds post emerge in soybeans, and to a lesser extent in corn, it will take knowledge of the risks associated with these traits and their accompanying herbicides along with what herbicides you can use on them. First you have to understand what each trait contains, and the limitations around them.

The Enlist trait from DOW Agrosciences in soybeans will be tolerant to 2,4D, and not Dicamba. While these herbicides have the same mode of action, plant growth regulators or PGR's, they do not have the same site of action. The Enlist trait in corn will include 2,4D tolerance along with tolerance to "Fop" grass herbicides like Assure II and Fusilade DX. This is nice in that we can use new effective grass control herbicides in Enlist corn, but also frustrating when it comes to volunteer corn control in soybeans. This will take away two very effective, low rate, and cheap volunteer corn herbicides in soybean fields following Enlist corn. The problem here for retailers will be knowing who had Enlist corn the previous year along with what happens when you show up with a Fop in your tank. Likely, we will have to switch to products like Select Max as our only options to control volunteer corn.

The Roundup Ready 2 Xtend soybeans trait will be tolerant to Dicamba, and not 2,4D. This trait is nice in that it will add the ability to do burndowns with Dicamba with no plant back restrictions to

Xtend soybeans. With the better crop safety of our Dicamba based corn herbicides there is no reason to add this trait to corn. There are no grass herbicide traits built into this as well so no worries about volunteer corn herbicides.

You also have to understand what these herbicides do, and the forms we will have to use on these traits. DOW will be coming out with only one form of 2,4D that will be labeled to use on Enlist tolerant crops. Enlist Duo will be the herbicide that DOW releases, and it contains a premix of glyphosate (Roundup) and 2,4D choline, a new form of 2,4D that will be less volatile. Generic 2,4D's that we commonly use on crops will likely not be labeled for use in Enlist crops so using them will be an off label application. In Enlist corn we will be able to use Fop grass herbicides, but they will also have to be labeled for application and will be up to the chemical company to determine if they are going to apply for a new label or supplemental label. Until that happens these applications will also be off label. While 2,4D is a good broad leaf chemical, it will have to be managed for drift, volatility, and potential resistance. There is also very little residual activity with 2,4D.

Monsanto will be coming out with their own premix as well to be used on Roundup Ready 2 Xtend soybeans. This premix will include glyphosate (Roundup) and a lower volatility form of dicamba. One nice thing about Xtend beans is there will be a label on Clarity from BASF to allow it to be applied to these soybeans along with straight Dicamba call Xtendimax from Monsanto. Attention will have to be paid to not using Dicamba formulations meant for corn like Status, Banvel, and Distinct. These products contain a safener meant only for corn so you can't spray corn with these herbicides and not rinse your tank, or hang your boom into soybeans with the Xtend trait. There is slightly better residual to Dicamba, don't expect much more than about 2 weeks of activity. So you still need to consider a pre residual, or a post residual. There will also still be drift, and volatility concerns with Dicamba.

Most retailers are slightly wary of this technology due to confusion between the traits and what can be used on them, along with potential for tank contamination with both 2,4D and Dicamba. There are also concerns with some seed companies using both traits in their lineup leading to even more confusion. Think Roundup Ready launch with the potential for more tank contamination issues. Like any other herbicide trait, we will have to make sure to apply following label recommendations. There are already a couple of weeds with resistance or suspected resistance to 2,4D. Managing drift, and volatility around sensitive crops along with tank proper tank rinse procedures will be things retailers and farmer applicators will have to pay more attention to.

Farmers are cautiously optimistic here where we have little to no resistance issues, I can't imagine how happy those that are in heavy weed resistance are about this trait. These traits are just the first in a line of new herbicide traits coming to soybeans. While these are a step in the right direction, it's important to remember the weed spectrum you are targeting, and respecting labeled rates. There will inherently be some growing pains as we adjust to new traits, but if we can overcome them this should help us all in managing weed resistance.

|

| PGR injury to soybeans |

The Enlist trait from DOW Agrosciences in soybeans will be tolerant to 2,4D, and not Dicamba. While these herbicides have the same mode of action, plant growth regulators or PGR's, they do not have the same site of action. The Enlist trait in corn will include 2,4D tolerance along with tolerance to "Fop" grass herbicides like Assure II and Fusilade DX. This is nice in that we can use new effective grass control herbicides in Enlist corn, but also frustrating when it comes to volunteer corn control in soybeans. This will take away two very effective, low rate, and cheap volunteer corn herbicides in soybean fields following Enlist corn. The problem here for retailers will be knowing who had Enlist corn the previous year along with what happens when you show up with a Fop in your tank. Likely, we will have to switch to products like Select Max as our only options to control volunteer corn.

The Roundup Ready 2 Xtend soybeans trait will be tolerant to Dicamba, and not 2,4D. This trait is nice in that it will add the ability to do burndowns with Dicamba with no plant back restrictions to

Xtend soybeans. With the better crop safety of our Dicamba based corn herbicides there is no reason to add this trait to corn. There are no grass herbicide traits built into this as well so no worries about volunteer corn herbicides.

You also have to understand what these herbicides do, and the forms we will have to use on these traits. DOW will be coming out with only one form of 2,4D that will be labeled to use on Enlist tolerant crops. Enlist Duo will be the herbicide that DOW releases, and it contains a premix of glyphosate (Roundup) and 2,4D choline, a new form of 2,4D that will be less volatile. Generic 2,4D's that we commonly use on crops will likely not be labeled for use in Enlist crops so using them will be an off label application. In Enlist corn we will be able to use Fop grass herbicides, but they will also have to be labeled for application and will be up to the chemical company to determine if they are going to apply for a new label or supplemental label. Until that happens these applications will also be off label. While 2,4D is a good broad leaf chemical, it will have to be managed for drift, volatility, and potential resistance. There is also very little residual activity with 2,4D.

Monsanto will be coming out with their own premix as well to be used on Roundup Ready 2 Xtend soybeans. This premix will include glyphosate (Roundup) and a lower volatility form of dicamba. One nice thing about Xtend beans is there will be a label on Clarity from BASF to allow it to be applied to these soybeans along with straight Dicamba call Xtendimax from Monsanto. Attention will have to be paid to not using Dicamba formulations meant for corn like Status, Banvel, and Distinct. These products contain a safener meant only for corn so you can't spray corn with these herbicides and not rinse your tank, or hang your boom into soybeans with the Xtend trait. There is slightly better residual to Dicamba, don't expect much more than about 2 weeks of activity. So you still need to consider a pre residual, or a post residual. There will also still be drift, and volatility concerns with Dicamba.

|

| Dicamba injury to soybeans from improper tank rinse out |

Most retailers are slightly wary of this technology due to confusion between the traits and what can be used on them, along with potential for tank contamination with both 2,4D and Dicamba. There are also concerns with some seed companies using both traits in their lineup leading to even more confusion. Think Roundup Ready launch with the potential for more tank contamination issues. Like any other herbicide trait, we will have to make sure to apply following label recommendations. There are already a couple of weeds with resistance or suspected resistance to 2,4D. Managing drift, and volatility around sensitive crops along with tank proper tank rinse procedures will be things retailers and farmer applicators will have to pay more attention to.

Farmers are cautiously optimistic here where we have little to no resistance issues, I can't imagine how happy those that are in heavy weed resistance are about this trait. These traits are just the first in a line of new herbicide traits coming to soybeans. While these are a step in the right direction, it's important to remember the weed spectrum you are targeting, and respecting labeled rates. There will inherently be some growing pains as we adjust to new traits, but if we can overcome them this should help us all in managing weed resistance.

Tuesday, April 15, 2014

Why Is Weather So Important To Farmers?

|

| Our weather station at home |

|

| Part of the office weather station in Mapleton |

Once the crop is growing we also need timely weather as well. During corn pollination we can lose yield if the temperature gets above 90F or the night time temperature doesn't get below 70F since the pollen won't last as long in the heat and if the night doesn't get cool enough the plant can't rest. In 2012, we had farmers lose up to 100 bushels of corn per acre when the temperatures were over 100F during pollination. The same can be said about timely rainfall. In soybeans we need rain in late July and early August to maintain yield along with increase seed size and keep pods from aborting. In this window a 1" rain will typically add around 5 bushels of yield in soybeans or around $55/acre.

|

| A RadarScope screen shot from 2013 |

There are several more scenarios where we can gain or lose yield based on the weather, but in the grand scheme of things it accounts for up to 70% of our overall yield every year. I don't think there is any other profession out there where an ever changing variable that no one has control over is the main thing you depend on for income. These are the reasons I and our customers pay so much attention to the forecast (and are often upset when it's wrong). So the next time you're mad your lawn is brown, think of that guy who has their whole life invested in something that looks like your lawn and help us pray for rain.

Friday, March 28, 2014

The Importance of Planting Depth

We often hear that you should shallow up your planting to get seed out of the ground faster, or plant deeper to get to moisture. That being said I have also heard that you don't need to worm sheep if you feed them oats, "it spears the worms" as one farmer back home used to say. You tell me which one sounds the worst. While there is some truth to planting deeper in times of extreme drought or when you work too far ahead of the planter, the other two sayings have little merit.

The name of the game really is uniform emergence and putting the seed in a place that will have little variation in temperature and moisture. In the early spring these temperature swings are more likely as we often get those cold wet nights that will effect germination. Later in the season getting seed out of the ground fast is not really an excuse, as soil temperatures warm up I have seen corn come out of the ground in less than 5 days planted 2.5" deep. Corn plants will also set brace roots at the same distance from the crown whether it's 1/2" or deeper so often we will find brace roots set higher on shallow planted corn. This can lead to brace roots burning off in dry soil conditions we often get in July and August.

So what is the ideal seed depth for corn? I'd say 2" is still a very good number, and in worked ground you need to account for 1/4" of settling. I often get the question, so where do I set my planter to get 2"? The best thing we can do is get out and dig. This depth will vary on down pressure, soil type, and planting conditions. This is something I would recommend doing on every field and checking every time you get out to fill the planter. I have seen all sorts of reasons this is a good idea. In the past two years I have seen broken seed disks, missing gauge wheels, and many other things go wrong that were missed for several passes. It's very hard to get a do over on one row across a field.

A seed firmer also helps with even planting depth to get every seed to the exact same depth. A big problem I have seen with some types of row units is that with offset seed disks and RID (Reduced Interior Diameter) wheels is we get seeds hanging up in the side walls from the lower angle of the disks and air pockets left from the bulge in the RID wheels. A firmer will often help with this, but not cure it entirely. These are all reasons I have preferred setups for each area I work in.

So before you head to the field this year, consider planting depth and consistent planting depth while you work on your planter. It's these little things that will determine if each corn plant is a good plant or a weed.

|

| Plant variation from 1" planting depth |

So what is the ideal seed depth for corn? I'd say 2" is still a very good number, and in worked ground you need to account for 1/4" of settling. I often get the question, so where do I set my planter to get 2"? The best thing we can do is get out and dig. This depth will vary on down pressure, soil type, and planting conditions. This is something I would recommend doing on every field and checking every time you get out to fill the planter. I have seen all sorts of reasons this is a good idea. In the past two years I have seen broken seed disks, missing gauge wheels, and many other things go wrong that were missed for several passes. It's very hard to get a do over on one row across a field.

A seed firmer also helps with even planting depth to get every seed to the exact same depth. A big problem I have seen with some types of row units is that with offset seed disks and RID (Reduced Interior Diameter) wheels is we get seeds hanging up in the side walls from the lower angle of the disks and air pockets left from the bulge in the RID wheels. A firmer will often help with this, but not cure it entirely. These are all reasons I have preferred setups for each area I work in.

So before you head to the field this year, consider planting depth and consistent planting depth while you work on your planter. It's these little things that will determine if each corn plant is a good plant or a weed.

Subscribe to:

Posts (Atom)